- Bhosari, Pune-411039

- akenterprises7373@gmail.com

- +91-8149729746

Are you trying to find MIG welding machines of the highest caliber in India? The MIG-400/500/630 series from AK Enterprises Pune is the only option to consider. MIG-400/ 500/ 630 welding, sometimes referred to as metal gas arc welding (GMAW), is a very flexible technique that includes both metal active gas (MAG) and metal inert gas (MIG) welding. With its remarkable welding rates, MIG-400/ 500/ 630 welding is now the most popular welding technology and may be utilized for a wide range of applications.

In addition to being experts in MIG welding equipment, we at AK Enterprises Pune also take pride in being India's top producers of saw welding and saw welding automation equipment . Outstanding performance is what our MIG-400/500/630 series is designed to give, whether it is operated mechanically, robotically, or manually. Our MIG welding equipment provides unmatched dependability and efficiency, whether they are operated manually or through automated systems.

As one of India's biggest manufacturers of saw welding machines, AK Enterprises Pune is known for its high-quality MIG-400, MIG-500, and MIG-630 models. These cutting-edge devices, which highlight our leadership in saw welding automation machines in India, are a testament to our dedication to perfection. Our MIG series offers exceptional performance and dependability and is designed to satisfy the demanding needs of contemporary industrial applications.As one of the top manufacturers of saw welding machines in India, we make sure that the newest technology is included in the MIG-400, MIG-500, and MIG-630 models to improve the accuracy and efficiency of the welding process. These and other variants of our saw welding automation machines in India are designed to increase overall productivity and simplify processes.

The MIG-400, MIG-500, and MIG-630 models provide excellent performance and versatility and are essential for accurate and efficient welding operations. These devices guarantee excellent welds, cut down on downtime, and boost output all around. As saw welding automation machines in India, we offer cutting-edge solutions to meet various industrial requirements. Selecting our saw welding automation machines in India would save you time and money by reducing the need for manual labor and increasing accuracy and operational efficiency. You can rely on AK Enterprises Pune to provide dependable and efficient welding solutions that satisfy your technical needs and enhance corporate success.

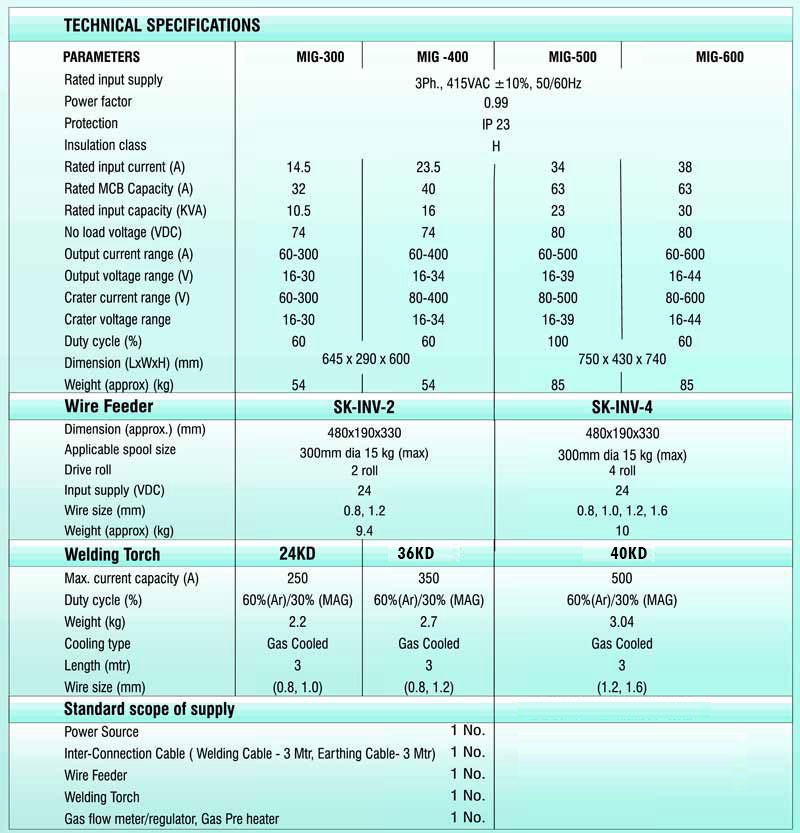

Soft-start ignition

Adjustable welding current/voltage, crater current/ voltage, arc characteristics control.

2/4 step welding mode selection facility.

Welding wire diameter selection facility.

Welding voltage and welding current displayed digitally.

Protective functions: over-temperature, over current, under/over voltage & single phasing etc

Designed with high open circuit voltage and slow wire feeding speed for smooth and steady arc striking / initiation.

Arc voltage and current feedback control circuit to make the welding process steady, strong adaptability for changes in the Arc length.

Excellent FTT - Globule control circuit makes positive striking of arc.

The function of crater filler, to improve the quality at the end of weld.

Multi function power source combining MIG/MAG, MMA, Scratch TIG and Carbon Arc Gouging.

Industrial standard quality, durable structure

Multi-processes, including stick, simple TIG, GMAW and gouging

Unique IGBT soft switch technology guarantees higher efficiency and longer lifespan

2/4T work cycle, suitable for short/long weld seam

Automatic creep start and burnback, greatly improve arc start performance

Crater filling current and voltage controlled

Arc control, choose the balance between deep penetration and less spatter

Arc force control in MMA process

High duty cycle at 40C and 10 minutes condition, up to 60%

1 Power source

1 Connected primary cable L=3m

1 Ground cable L=3m

1 Gas-cooled (or watercooled) torch L=3m

1 Wire feeder with Europe connection

Process: CO /MAG (GMAW) /Stick (SMAW) / Simple TIG (GTAW)/ Gouging

Shipbuilding and offshore engineering

Machinery industry

Metal shop

Industry plant construction